WARNING : Drilling, sawing, sanding or machining wood products can expose you to wood dust, a substance known to the State of California to cause cancer; Avoid inhaling wood dust or use a dust mask or other safeguards for personal protection. For more information go to www.P65Warnings.ca.gov/wood.

WARNING: This product can expose you to chemicals including nickel and cobalt, which are known to the State of California to cause cancer and lead, which is known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

![[0, ]](/img/warning.png) California Proposition 65

California Proposition 65

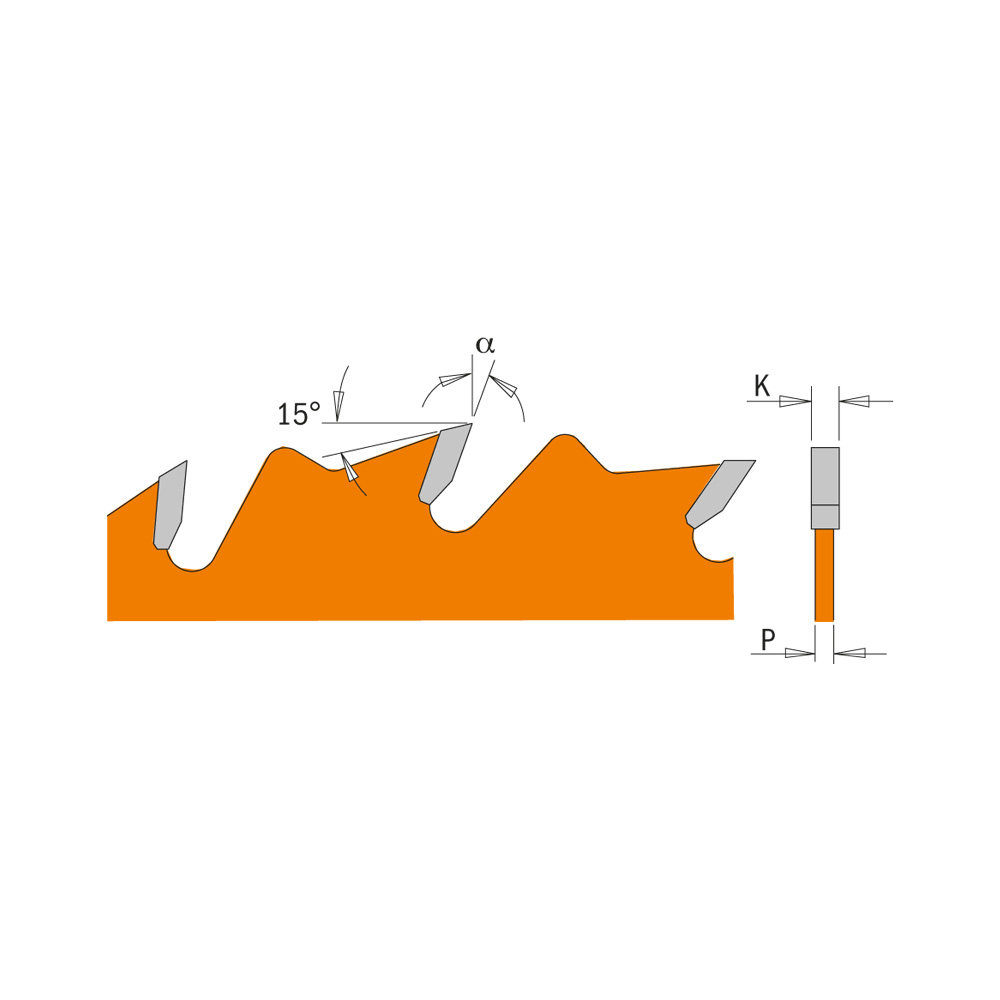

Industrial ripping circular saw blades

201

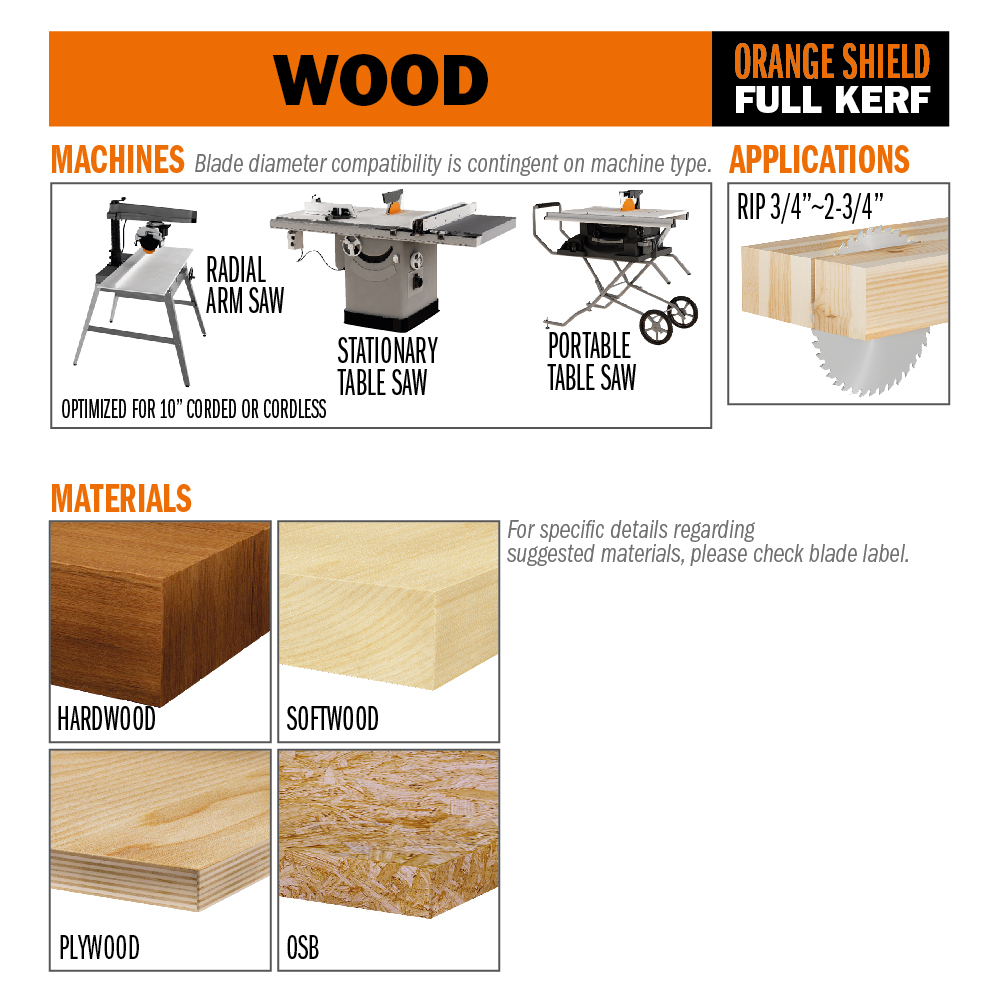

Application: for fast, smooth, heavy-duty rip cuts.

Machines: radial arm saws, miter saws, table and special saws.

Material: soft and hard wood.

Variations

Filter